What are CMYK colors and spot colors?

CMYK printing: to print using subtractive process with three primary colors (yellow, magenta, cyan) and black.

Spot color printing: refers to the printing process of using color inks other than the four colors (yellow, magenta, cyan and black). The spot color printing process is often used to print large areas of background of packaging boxes.

Features of Spot Color Printing

1. Accuracy.

Each color in the spot color has its fixed hue, which ensures the accuracy of the color during the printing process. Thus it largely solves the problem of the accuracy of the color transfer.

2. Solid nature.

Spot colors generally use solid color to define color, no matter how shallow this color is. Of course, it is also possible to add a spot color (Tint) to present the shades of the spot color.

3. Opacity.

Spot color ink is a kind of masking ink, which is opaque and can be covered in the field.

4. The color gamut is wide.

The color color field in the set of color stocks is very wide, which exceeds the performance color of RGB, not to mention the CMYK color space. Therefore, a large part of the color is not displayed by the four-color printing ink of CMYK.

Difference in Merits

For dark large-area color zones, the CMYK printing process is preferred, which may need to be superimposed by high-reduction dots of several colors. The ink layer is too thick to be easily presented on the reverse side; while the spot color printing process is used, only one printing is required. The color is not easy to present on the reverse side. The four-color printing process is adopted, and some parts of the graphic may be composed of several colors; and the spot color printing process is adopted, and only a color is printed on the corresponding part, thereby avoiding the possibility of displaying an overprint error.

Differences in printing process

1. Four-color printing passes through three subtractive primary colors (yellow, magenta, and cyan) and black printed color images. It is necessary for the color picture of the original used for printing to be separated into individual color separation sheets, and a black color separation plate is added to correct the inks of cyan, magenta and yellow to improve the blackness of the printed picture. These films are used to make four plates for four-color printing.

2, spot color printing, packaging products or the cover of books and periodicals often consist of uniform color blocks of different colors or regular gradient color blocks and text. These color blocks and texts can be color-coded and then printed with four primary colors. It is also possible to dispense a spot color ink and then print only one spot color ink at the same color block.

Difference in economic efficiency

From the point of view of economic efficiency, it is mainly concerned that the use of the spot color printing process can save the number of overprinting. Because reducing the number of overprints can save printing costs and save on pre-press manufacturing costs.

------------------------

Innove is a leading custom cardboard gift boxes supplier from China, offering various fancy setup gift box packaging products and custom box designs service. The product lines include personalized odd shaped boxes, round boxes, square boxes, rectangular boxes, telescoping boxes, shoulder boxes, cardboard drawer boxes, collapsible gift boxes - for clothing packaging, hexagon explosion gift boxes, cardboard window boxes, nesting gift boxes sets -stacking, etc. We've been serving diversified industries like gourmet cookie gift boxes, flat desserts boxes, cardboard flower gift boxes, jewelry gift boxes, luxury apparel boxes, t-shirt packaging boxes with clear lids, etc.

Innove Packaging: professional cardboard gift boxes manufacturer from China.

Subscribe to:

Post Comments (Atom)

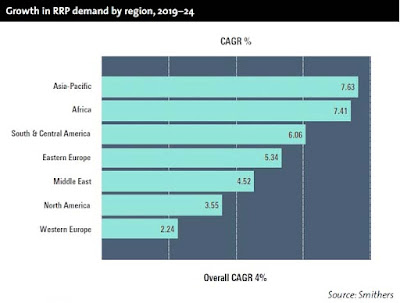

Emerging economies drive retail packaging growth

According to Smithers Pira's latest report, The Future of Retail-Ready Packaging to 2024 , demand growth for retail ready packaging s...

-

As a leading China cardboard gift boxes manufacturer , Innove Packaging is the right choice for your gift boxes. But before you decide how a...

-

According to Smithers Pira's latest report, The Future of Retail-Ready Packaging to 2024 , demand growth for retail ready packaging s...

-

With the development of the Internet and mobile Internet, there are more and more industries and companies with various design needs, and th...

No comments:

Post a Comment